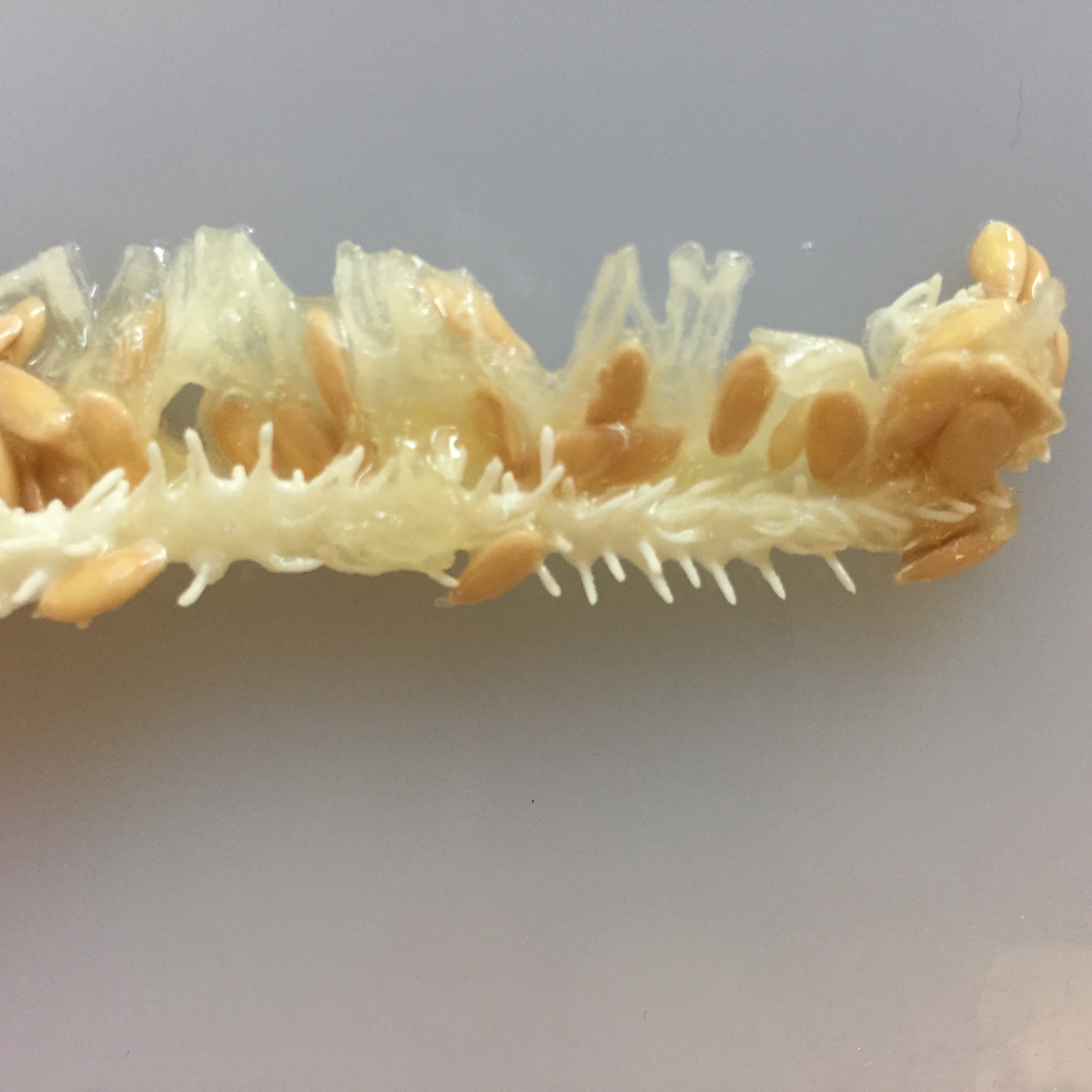

Throughout the rest of this project, I took a ton of photos. I focused on the process and stages that led me to two final outcomes. Looking at found textures and forms from products found at stores and those which come from "waste" – packaging used in fruit shipping. Attached are the final containers that I developed. The plaster form was my final, but I kept working to challenge myself to explore another material, cement. Thus, I contrasted plaster and cement in their contrast with paper pulp packaging. The cement was able to grip onto the packaging and incorporated the color into its surface unlike the softer plaster that remained much purer without much packaging remains adhering to its exterior surface. The methods with cement left a more dynamic form than plaster that signals more of a artistic bust and lifted textual/symbolic elements from the packaging. Both containers have an opening, but the cement body has an open void, unlike the plaster which is a drilled out doweled burrow.

Reflecting from the critique, my material exploration did not meet the expectations of my reviewers. I enjoyed this process and my methods of vacuum forming, jump between different casting experiments and surfaces, but understand what to do going into future work with a level of design intent that show progressing from point to point in a node-network that typical people can follow, but ultimately a matter of logical order would have been preferred. Too many conceptual arguments were made and lost in the outcomes of my work in retrospect.

Below is an exhaustive library of my process and experiments for the project. Additionally, I am attaching my presentation file to this post.